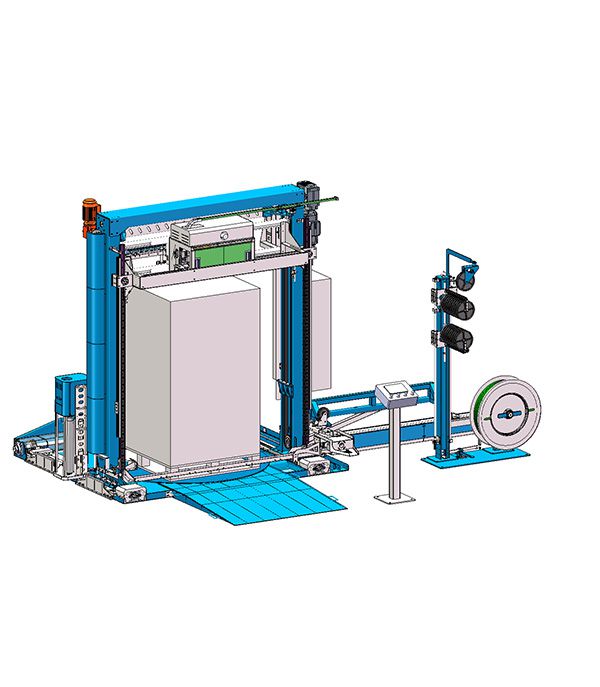

● Fully automatic strapping machine for both PET and PP. Servo drive moving frame is suited to different pallet sizes.

● Fully automatic wrapping machine with 250% pre-stretch

● Operation guidance (show on screen) Smart Alarm & solution find in screen

● Fully automatic cutting and clamping film

● Remote start machine

● Ultrasonic Strapping Head SIEMENS Electric parts, SICK sensor...

● 3 years Warranty for Strapping Head

● IoT remote service +7x24 technical support service

1800mm Turntable with maximum 1500KG load weight, maximum suitable for 1.25x1.25m pallet.

Suitable for all kinds of pallet shape (Straps Though Hole Should over 250mm lengthx80mm high)ramp for hand pallet jack to load the pallet on machine.

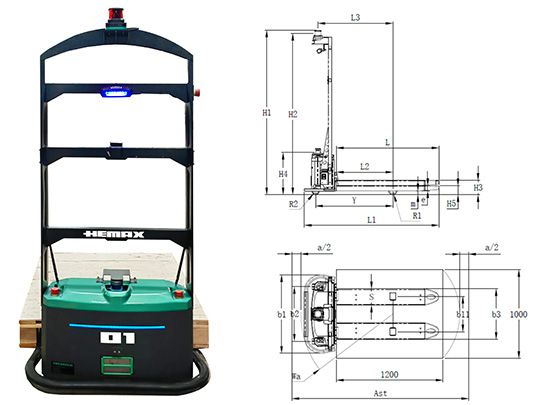

1000KG maximum load weight, Lifting Height 174mm, fork Height 104

Laser Radar + 3D Havcam

8 Hours working time

Accurate Positioning +/- 10mm

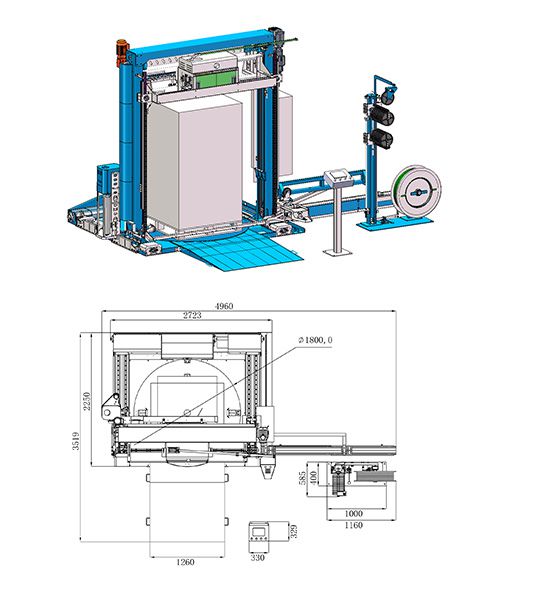

| MK900 TECHNICAL DATA | MK900 STANDARD FEATURES | ||||||||||

| Performance: | Strapping Head | Top-mounted Utrasonic SEPOII | |||||||||

| Packing speed : | Approx. 25-30 pallet/hour (Depending on product height and width) | PLC Control | SIEMENS | ||||||||

| Inverter | SIEMENS | ||||||||||

| Maximum pallet size | 1200mm*1200mm(EUR-pallet) | Touch Screen | Mastek IoT Screen /SIEMENS | ||||||||

| Maximum load height | 500mm(standard)- 1500mm | Up and down motor | SEW motor | ||||||||

| Minimum load size | 1000*800mm(W*H) | Sealing head motor | Servo motor | ||||||||

| Maximum load weight | 800KG(2000KG Optional) | Sword moving motor | Servo motor | ||||||||

| Tension range | 500-3000N (adjustable) | movable frame motor | Servo motor | ||||||||

| Straps feeding speed | 2m/second | Sensor | SICK | ||||||||

| Joint sealing length | 30mm | Turntable type | 1650mm M shape | ||||||||

| Straps | System Recipe | 12 Modes | |||||||||

| PET | 1208(12mm wide/0.8mm thickness) | Film carriage pre strech rate | 2.5 | ||||||||

| 1508(15mm wide/0.8mm thickness) | Cutting and clamping film | Full automatic | |||||||||

| 1908(19mm wide/0.8mm thickness) | Strap tension Adjustable via touch panel | ||||||||||

| PP | 1510(15mm wide/1.0mm thickness) | Sealing unit self clean system | Have | ||||||||

| Stretch Film | End of strap signal | Automatic detect | |||||||||

| 10-15KG 500mm high 14-23mic 300% stretch rate | |||||||||||

| 230mm diameter 76mm paper core | |||||||||||

| Strap Coil Dispenser: | Certification | CE | |||||||||

| Maximum Coil size | 600-760mm diameter* 150mm width | Technical support | 24hrs x7 days a week | ||||||||

| Coil Inner diameter | 406mm+10mm | Machine Warranty | One year (3 years for strapping head) | ||||||||

| Pneumatic Data | |||||||||||

| Air consumption | 2-3CFM @ 60-80 PSI | Optional | |||||||||

| Electricity: | ①Turntable | 2000KG load turntable with Ramp | |||||||||

| Power consumption: | 7KW | ②AGV | HEMAX 01 | ||||||||

| Voltage | 380V /415/480V/50or 60Hz 3phase | ③Top Protection sheet folding device | For 5mm Paper sheet | ||||||||

| Machine weight | 1800KG | ④Top edge protector applicator | 100pcs *100mm*50/50mm*5mm (paper) | ||||||||

| Machine size | 3902*1581*2388mm | ⑤Strapping head | Friction type (Only PET) | ||||||||

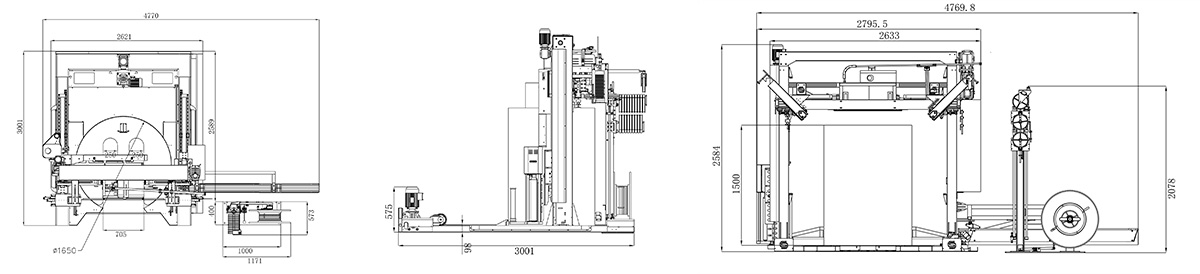

DIMENSIONS OF MACHINE (in mm)

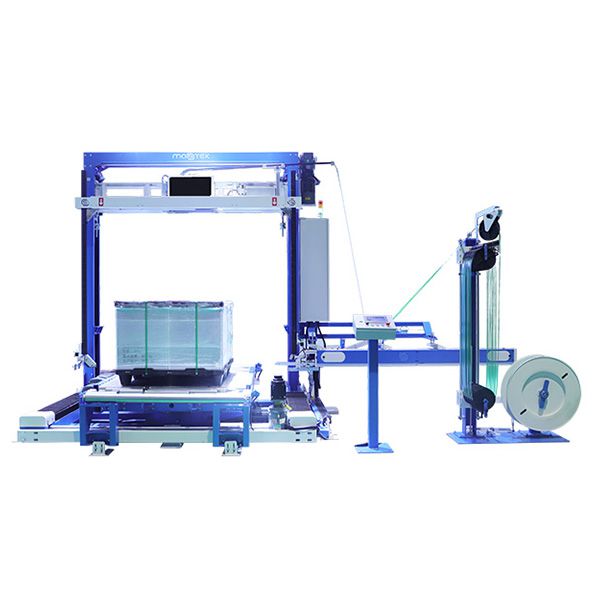

Background:

A large food and beverage manufacturing company faced challenges with pallet stability during storage and transportation. Manual strapping was inconsistent, leading to product damage and increased labor costs. The company decided to invest in a Fully Automatic Pallet Strapping Machine to streamline the process.

Objectives:

Improve pallet stability and reduce product damage.

Increase efficiency and consistency in the strapping process.

Reduce labor costs and manual errors.

Ensure compliance with transportation safety standards.

Solution:

The company installed a Fully Automatic Pallet Strapping Machine at the end of the production line. The machine was integrated with the existing conveyor system to automatically strap pallets after they were loaded with products.

Key Features of the Machine:

Automatic detection of pallet size and shape.

High-speed strapping with adjustable tension settings.

Integration with the conveyor system for seamless operation.

Durable and adjustable strapping materials suitable for various loads.

Results:

Enhanced Stability: The strapping machine significantly improved the stability of pallets, reducing product damage during storage and transit by 40%.

Increased Efficiency: The fully automated system reduced the time required to strap each pallet, increasing throughput by 25%.

Cost Savings: The company saw a 30% reduction in labor costs as manual strapping was no longer required.

Improved Safety: The machine ensured consistent tension on each strap, meeting industry standards and reducing the risk of accidents.

ROI: The investment in the machine paid off within a year due to the savings in labor costs and reduced product damage.

Conclusion:

The implementation of a Fully Automatic Pallet Strapping Machine transformed the company’s packaging process, improving both efficiency and product safety. The machine not only reduced operational costs but also enhanced the overall quality of the packaging, leading to better customer satisfaction.