Japan Technology Sealing Head

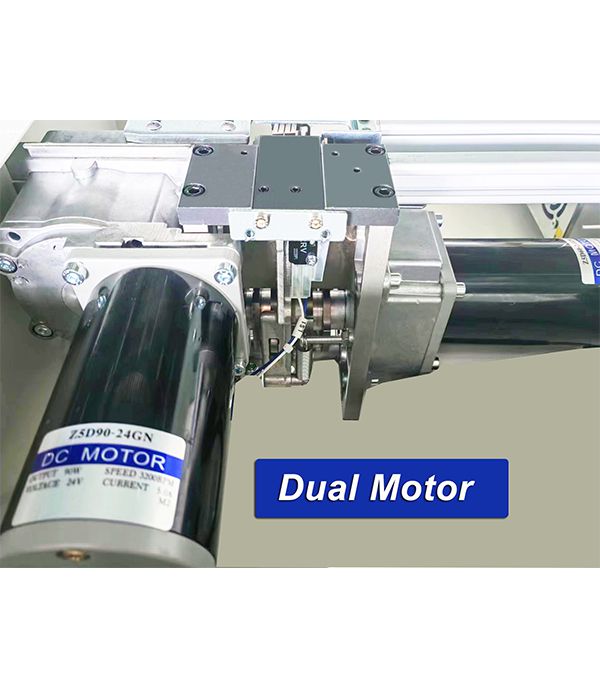

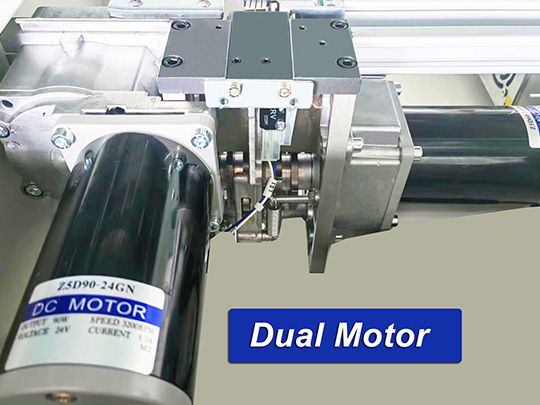

Dual DC motor>30,0000 times

Durability and Build Quality: Since semi-automatic strapping machines are designed for industrial use, they often feature sturdy construction and durable components to withstand the rigors of continuous operation.

Straps delivery out automatic

Soft tightening straps during work

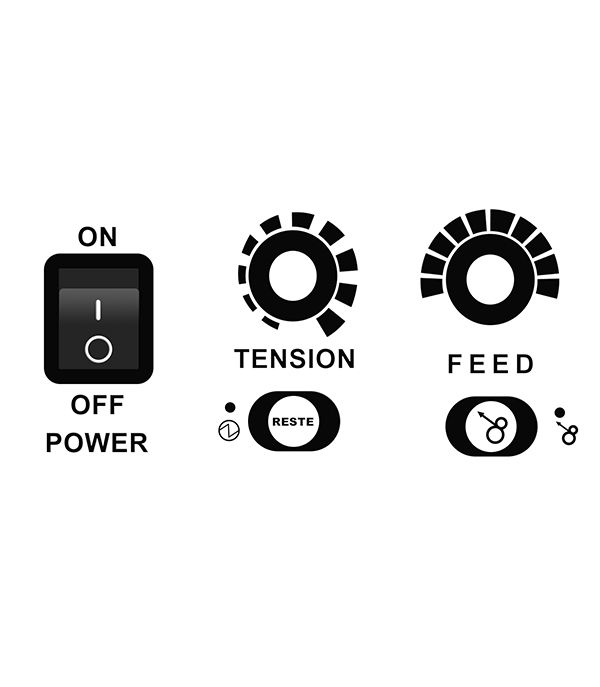

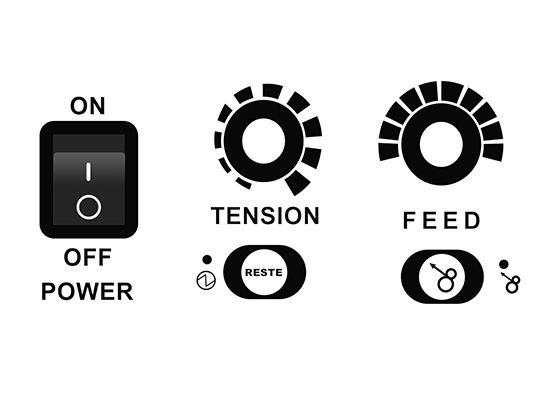

Intuitive controls and interface make it easy for operators to set up and operate the machine efficiently.

Electrical tension adjustment

Electrical Fix Length adjustment

Allows users to adjust the tension of the strap according to the package's requirements, ensuring secure but not overly tight strapping. Semi-automatic PP strapping machines can usually accommodate different widths of plastic strapping, allowing flexibility in packaging various-sized items. An efficient strap feed system ensures smooth and consistent feeding of the plastic strap, reducing the chances of jams or disruptions during the strapping process.

Typically, semi-automatic strapping machines use a heat sealing mechanism to join the ends of the plastic strap securely.

This could include features like emergency stop buttons or sensors to prevent injuries or damage to the machine.

The Semi-auto strapping machine comes with troubleshooting guidance and is easy to operate.

The machine has global IoT capabilities and engineers provide remote services

We have agents in 31 countries, such as Thailand, Malaysia, South Korea, Australia, Canada, the United States and other countries.

Delivery time: 15-45 working days

Production capacity: 100sets/month

Minimum order: 1 set

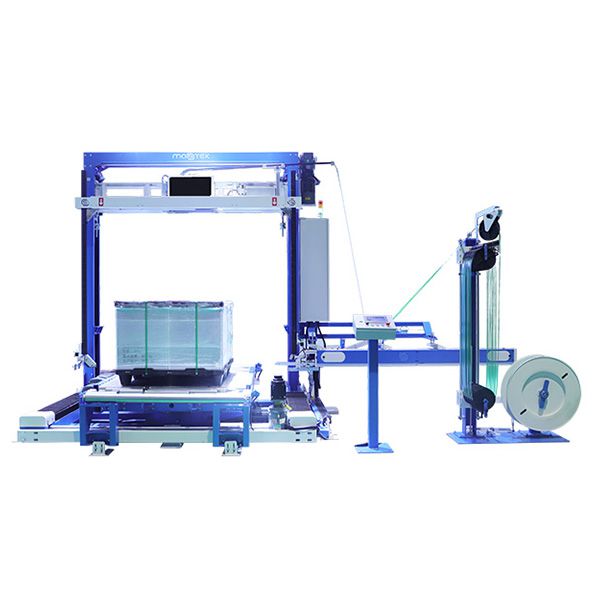

| TECHNICAL DATA | STANDARD FEATURES | ||||||||||

| Performance: | Motor type | DC motor | |||||||||

| Minimum strapping size | 60x30 mm | Control type | PCB ADC12 | ||||||||

| Strapping speed | </= 2.5 Seconds/Strap | Machine strapping head | Double motor | ||||||||

| Tension range | 3-50KG | Sealing method | Heat-weld sealing | ||||||||

| Table height | 760mm | Heating Device | nickel-chromium alloy material | ||||||||

| Straps | Ls1 switch | Panasonic | |||||||||

| PP straps width | 5mm-15.5mm | Knife holder | nickel phosphorus(10 years life) | ||||||||

| PP straps thickness | 0.4mm-1.0mm | eccentric shaft seat | Patent No. 201721854938.5 | ||||||||

| Strap Coil Dispenser: | Machine cutter | SKS-3 | |||||||||

| Coil Width | 200mm | ||||||||||

| Coil Inner diameter | 200mm | Certification | CE | ||||||||

| Maximum roll diameter | 450mm | Machine Warranty | 1 year | ||||||||

| Electricity: | |||||||||||

| Power consumption: | 300W | Optional | |||||||||

| Voltage | 220V/50Hz 1phase | ①Table Height | Low table 450mm Model :MK50s | ||||||||

| Machine weight | 65KG | ②Machine Frame | Full Closed | ||||||||

| Machine size | 780mm*545*760mm | ③Control Panel | Digital LCD | ||||||||

| Option① Description: Low table 450mm | Option② Description: Full Closed Verison | Option③ Description: Digital LCD Screen |

|  |  |