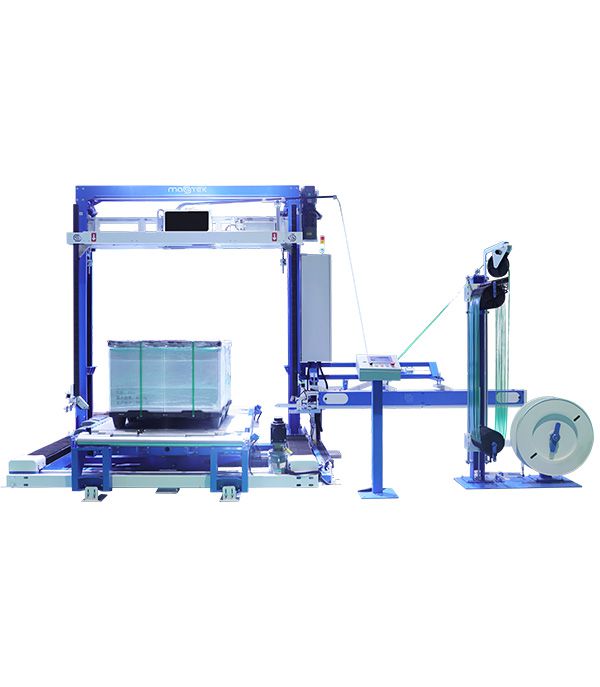

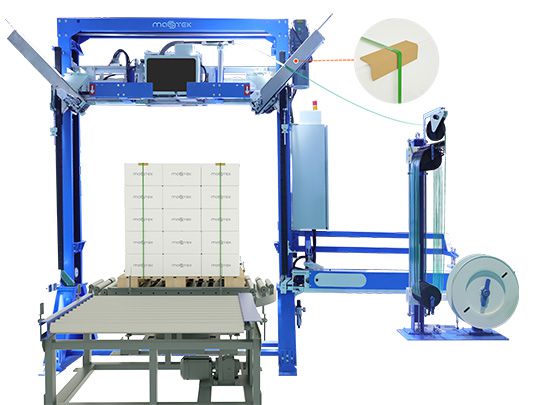

● Ultrasonic type SEPO II: Quiet & dust-free operation, up to 90% of strap breaking load Servo Motor drive system, strapping tension can be adjusted on the screen.

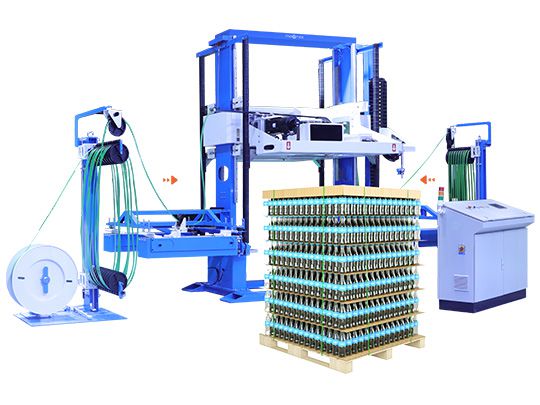

● 24 hours continuous operation, suitable for brick or wood fields

● Module Design:Quick Maintenance & quick exchange by 8 screws. Special inner design makes maintenance easier.

● MK300 pallet strapping machine adopts world-renowned key parts, such as SEW motor, Siemens PLC, Siemens inverter, SICK sensor.

● 3 year warranty for strapping head. Whether it is Mastek ultrasonic or friction strapping head, Mastek offers a 3-year warranty.

● IoT remote service +7x24 technical support. MK300 has an optional touch screen with IoT technology, and we can support customers online via remote control, with local Mastek distributor engineers providing on-site service.

●Operation guidance (shown in the screen)guides operator how to do the next step, it will be easier for operator to understand the machine, and use the machine smoothly.

●Automatic detection of straps end, improve the success rate of straps delivery. The load size is automatic adjusted by the electronic monitor, and the tension is consistent, so that each bundle of tension on different product sizes is the same.

●Smart alarms and solutions can be found on the screen. Operators or maintenance personnel can find alarm solutions on the on-screen alarm details page. MK300 system has just one monitor to show the working status of the machine and provides an alarm solution that makes maintenance faster and easier for customers.

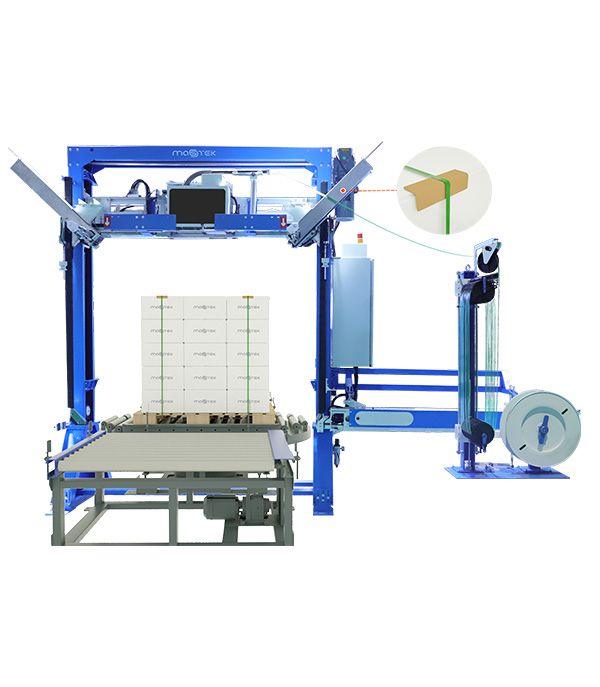

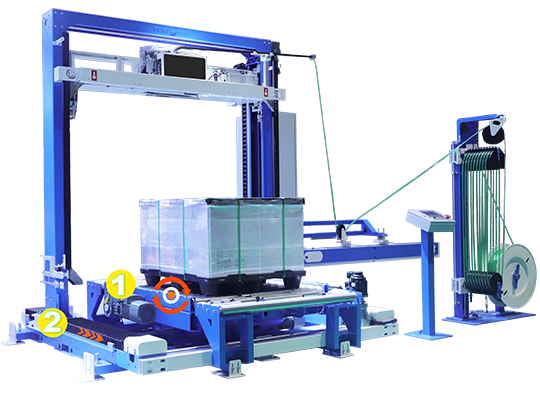

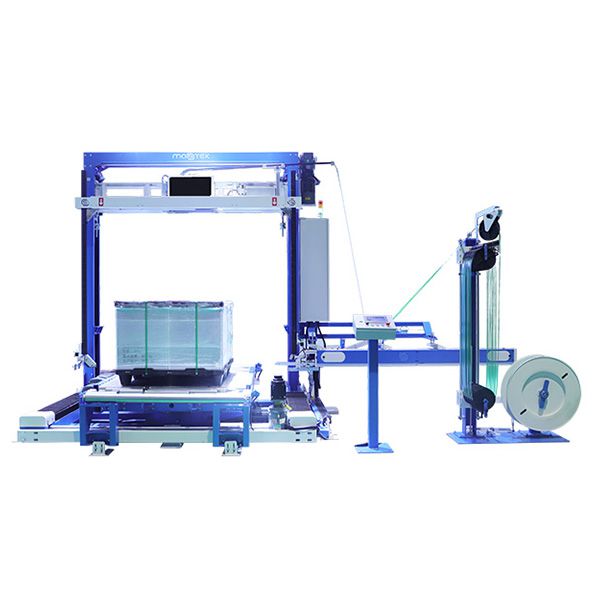

MK300 optional ① 90 turntable

Slew Bearing type turntable

No maintenance needed in the future, 400-750mm working height. Every 90 degrees rotation of the turntable, MK300 will pack a strap on the pallet. A total of 4 times of rotation, realize that each side of pallet have 2 straps, each strap position fixed, pattern: 2x2 2x0 0x2 bypass

MK300 optional ② Moving Frame:

a. If 2 strips are packed on the width side and the length side at the same time, the position of the strips can be different. MK300 will adjust the position of the strips according to the size of each side of the tray.

b.Make the machine fit pallets of different sizes, if there is no intersection of all pallet bottoms through the strapping holes, the moving frame will move the machine according to the size to fit it.

c.length or width side, if one side need strapping over 2 times

Moving frame + 90 turntable achieve pattern:2x3 3x3 3x2 2x2 2x0 0x2 bypass

MK300Pro Dual Strapping Head Pallet Strapping Machine

1.MK300pro with Strapping Head, 2 strapping belts can be completed at the same time, greatly improving the packaging efficiency, suitable for empty bottles and other unstable pallets.

2.If the product requires pressure function, such as cotton bag, chemical bag, battery material bag, MK300 Pro can choose a maximum of 500KG pressure top. The product is equipped with top pressure function before strapping.

Corners are automatically placed on the pallet to protect the soft product during strapping. Maximum 100 sheets, 50*50mm wide, 100mm long paper corners, rounded corners can also be used.

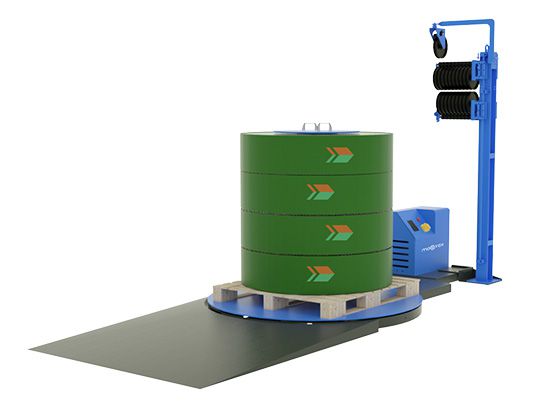

1500mm turntable, from 50-500kg PET coil, longer uptime, less coil replacement, greatly improving work safety. M-shaped turntable or ramp is optional.

MK300 batten feeder is a kind of custom functions, widely used in lumber field, can be used as one or at most three compartment version. Handle battens of different lengths.

| MK300 TECHNICAL DATA | MK300 STANDARD FEATURES | ||||||||||

| Performance: | Strapping Head | Top-mounted Ultrasonic SEPOII | |||||||||

| Single straps packing speed: Approx. 15-25 seconds | PLC Control | SIEMENS (with Ethernet communication) | |||||||||

| (Depending on product's height and width) | Inverter | SIEMENS | |||||||||

| Maximum load width (conveyor by MK) | 1200mm(standard)- 2200mm | Touch Screen | Mastek IoT Screen | ||||||||

| Maximum load height | 1500mm(standard)- 2500mm | Up and down motor | SEW motor | ||||||||

| Minimum load size | 800*500mm(W*H) | Sealing head motor | INOVANCE servo motor | ||||||||

| Sword moving motor | INOVANCE servo motor | ||||||||||

| Tension range | 500-3000N (adjustable) | Sensor | SICK | ||||||||

| Straps feeding speed | 2m/second | Cylinder | SMC(Only for friction type strapping head) | ||||||||

| Joint sealing length | 30mm | End of strap signal | Automatic detect | ||||||||

| Passage Sizes: | Sealing unit self clean system | Only for friction type strapping head | |||||||||

| Maximum through width for conveyor | 1500mm(standard)- 2500mm | ||||||||||

| Pallet through hole for straps | Minimum :150*80mm(W*H) | ||||||||||

| Conveyor height | 500mm (standard ) - others on request | ||||||||||

| Straps | Certification | CE | |||||||||

| PET | 1208(12mm wide/0.8mm thickness) | Machine Warranty | One year (3 years for strapping head) | ||||||||

| 1508(15mm wide/0.8mm thickness) | Technical support | 24 hours x7 days a week | |||||||||

| 1908(15mm wide/1.0mm thickness) | |||||||||||

| PP | 1510(15mm wide/1.0mm thickness) | ||||||||||

| Strap Coil Dispenser: | Optional | ||||||||||

| Coil diameter | 600-760mm | ①strapping head | Friction type | ||||||||

| Coil Inner diameter | 406mm+10mm | ②anti-explosion strapping head | Dust Proof level SEPOII (anti) | ||||||||

| Coil width | 150mm | ||||||||||

| Electricity: | ③90 degree turntable | Suit for 2 straps on each side | |||||||||

| Power consumption: | 2.5KW | ④Servo driven moving frame | Suit for different pallet size | ||||||||

| Voltage | 380V /415/480V/50 or 60Hz 3phase | ⑤Conveyor system | Roller /Chain/Salt conveyor | ||||||||

| Penumatic Data | ⑥Top Protection sheet folding device | For 5mm Paper sheet | |||||||||

| Air consumption | 2-3 CFM @ 60-80 PSI | ⑦Top edge protector applicator | 100pcs *100mm*50/50mm*5mm (paper) | ||||||||

| (only for friction strapping head) | ⑧Batten feeder | According to requirments | |||||||||

| Machine weight | 1200KG | ⑨Powered super jumbo dispenser | Motor driven turntable | ||||||||

| Machine size | 3902*1581*3116mm | ⑩Two straps packing at same time | MK300Pro +(two strapping heads) | ||||||||

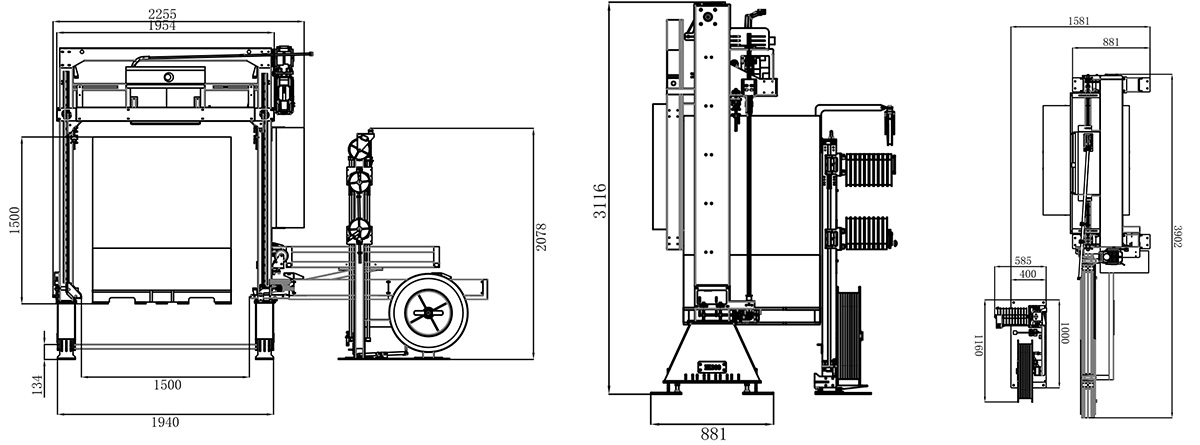

MK300 DIMENSIONS OF MACHINE (in mm)

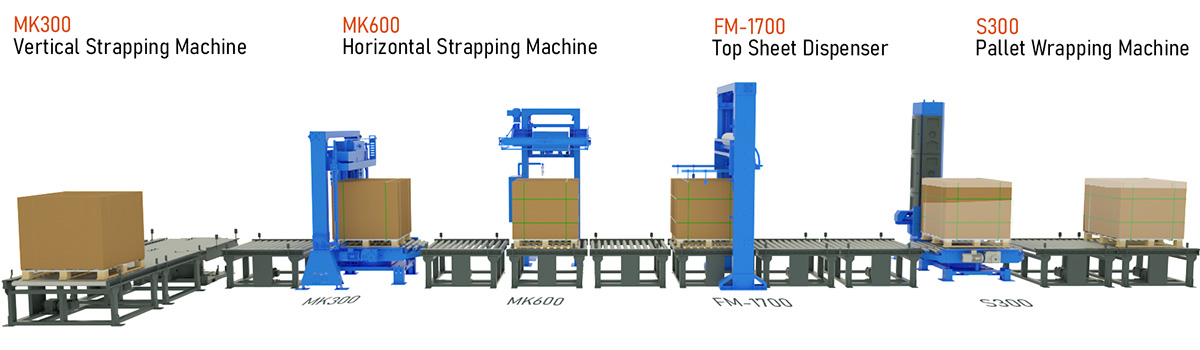

End Of Line Packaging Solution: