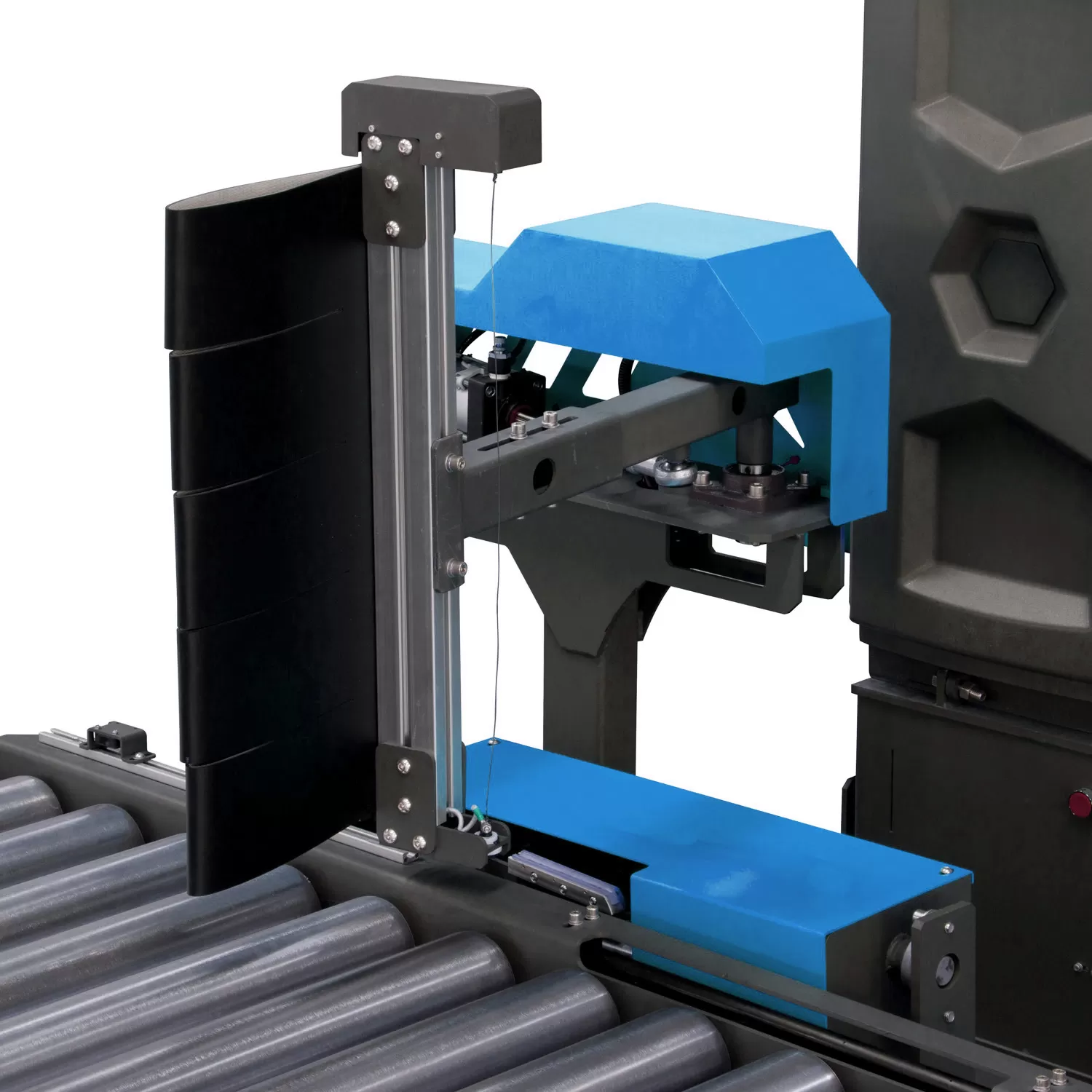

Bottom of the film will fold together to form a rope finally, film shrink rope grip to pallet & products during wrapping.

1. During transporting, there is no need to worry about the product falling when the pallets shakes violently.

2. If the forklift damages the film at the bottom of the pallet, the film still won't break.

3. Pallet bottom grip system and whole journey gripping can replace the horizontal strapping machine

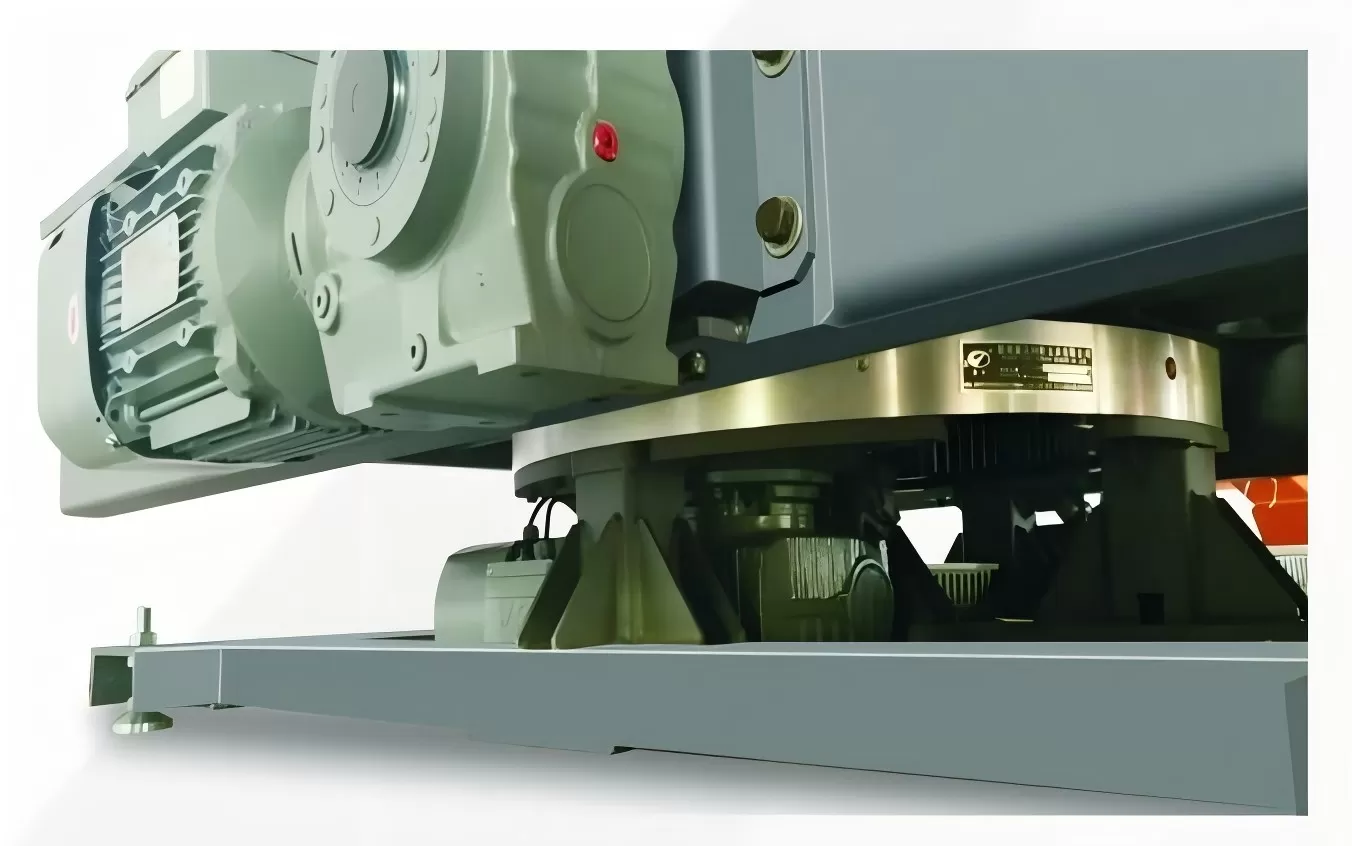

Online pallet wrapper uses the slewing bearing turntable, max load weight 3000KG, more quiet and lower vibration compared with the chain drive turntable.

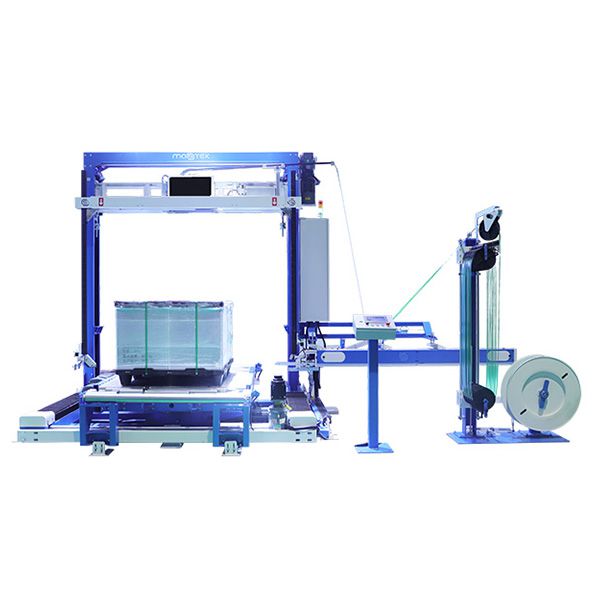

Online pallet stretch wrapper's electric parts all installed inside of the machine.

Do not use an independent control box anymore, in this way, it will be much easier to install the machine.

All the electric parts just use top brands like SIEMENS and OMRON.

Good spare parts are very important for the quality of the machine.

Pallet shrink wrap machine use 89mm stainless steel roller, the joint conveyor on the wrapper which need be linked to input & output conveyor also use chain drive so that the pallet can be moved from the conveyor to wrapper smoothly.

S300 pallet stretch wrapping machine, the worker just needs to put the pallet on the turntable and press the remote control button, the machine will start wrapping the pallet automatically, during this time, the worker does not need to get off the forklift truck and operate the machine by hand.

Automatic cut and clamp film system, which let workers no need use their hands to cut film and put the film on pallets anymore, cut &clamp film system will do it automatically.

| Model | S300 | Spare Parts | Brand |

| Maximum wrapping speed | 30-40 loads/hour | Inverter | X-Line |

| Load Size Diagonal | 1753mm | Position sensor | SICK(Germany) |

| Maximum Wrapping Height | 2400mm | PLC | SIEMENS(Hongkong) |

| Turntable Speed | 0-15RPM(Adjustable) | Travel Switch | OMRON(Japan) |

| Turntable Size | 2000mm | Motor | GPG |

| Turntable Drive | 1.5PH | Relay | OMRON(Japan) |

| Film &Clamp Cut | Automatic (Heat type) | Touch screen | SIEMENS 7inch |

| max load weight | 3000KG | Switch | Schneider |

| Standard Film Width | 500mm | ||

| Constant Film Delivery Force | Standard | ||

| Standard Pre-Stretch | 300% pre-stretch | ||

| Roller Materials | Stainless Steel 201 diameter :89mm | ||

| Film Capacity | 250mm Diametery | Special Process | Introduction |

| Film Delivery System | Power Roller -Stretch Plus | Frame | Steel+ABS |

| Film Rope System | Standard | Printing | Metallic Paint |

| Weighing Scale | Optional | Fall-proof | Inside Safety Belt |

| Machine Weight | 980KG | Cutting | Laser |

| Machine Size | L:2000mm W:1800mm H:3700mm | Turntable Roller | Double Nylon Roller |

| Truntable technology | Slewing Ring | Up&Down Drive | Belt |

| Voltage | 380V/220V/50HZ 1phase | Up&Down Guideway | Double Balance Device |

Benefits of a fully automatic wrapping machine

One of the primary benefits of a fully automatic wrapping machine is its ability to operate continuously with minimal human intervention. Once the machine is programmed and set up, it can run for extended periods without the need for frequent manual adjustments or monitoring. This can help businesses achieve higher production volumes and faster throughput rates, improving overall productivity and profitability.

FAQ about Fully Automatic Pallet Wrapping Machine

1. what's the mast height of the pallet shrink wrap machine?

S300 pallet wrapping machine mast height is 3200mm, and the max packing height is 2400mm, if you pallet over 2400mm, you need to choose a mast height of 3900mm, the max packing height of 3200mm

2. How to choose a control system?

S300 pallet wrapping machines all use Siemen's control system. Top-brand spare parts ensure a longer machine lifespan.

3. What's the turntable size?

The standard turntable size is 2000 mm

4. What temperature can be used?

standard machine needs> 0 degrees, if <0 degrees, need tell us, we need to use a special motor for machine

5. What's the turntable height?

turntable height 550mm adjustable

6. What's the maximum weight that can be used?

our standard pallet stretch wrapper max load weight is 3000KG

7. Weather need an air compressor for the machine?

Yes, need an air compressor

The best solution for automatic production line:

1. Motor Drive Conveyor

2. The Pallet Shrink Wrap Machine uses LLDPE stretch film as the main packing material to wrap the bulk cargo stacked on the pallet

3. Shrink Film provides extra support during transportation and storage to protect them from dust, moisture or damage

4. The Pallet Shrink Wrap Machine has been widely used in industries such as glassware, tools, electric & electronic, paper, pottery, food & beverage, etc.

Warehouses and Distribution Centers: Automates the final step in the packaging process, wrapping pallets ready for shipping.

Manufacturing Plants: Useful for industries such as food, pharmaceuticals, chemicals, and consumer goods that require high volumes of wrapped pallets.

Logistics and Freight: Ensures that goods are wrapped securely for safe transport, particularly in industries like e-commerce and retail.

Export and International Shipping: Ideal for wrapping goods that need to be transported internationally, providing extra security against the elements.