1. SIEMENS PLC

2. SIEMENS Touch screen

3. SMC Vacuum Generator

1. All Sensor monitored by PLC

2. All Sensor with Visible Label

3. All Sensor with Visible Light

1. Pre-caution for Tape used up

2. Pre-caution for empty carton/box used up

3. Safety Door System

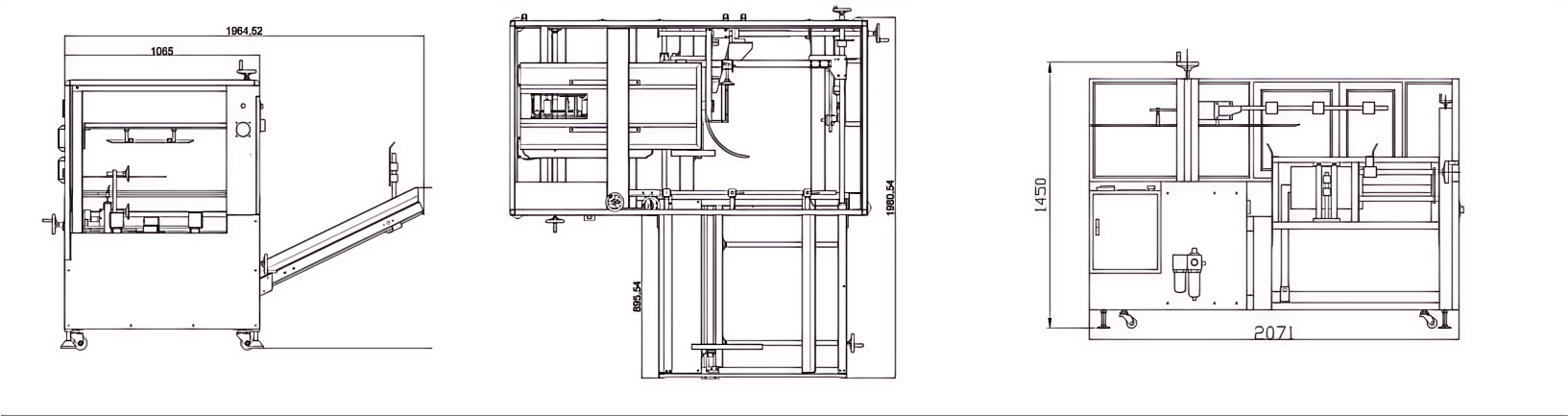

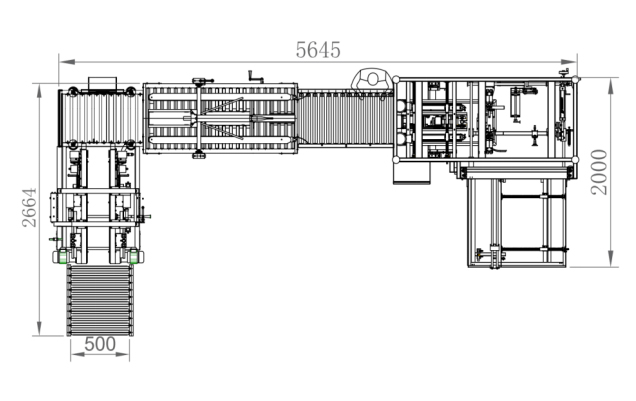

FOR maximum 500mm wide 600mm Length box

Remark: Width on left Size(front view), output side on right

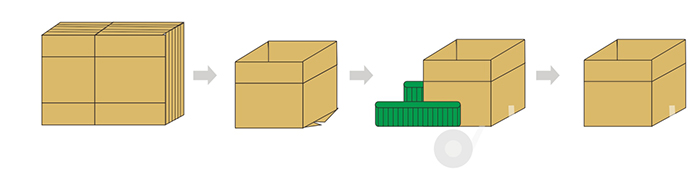

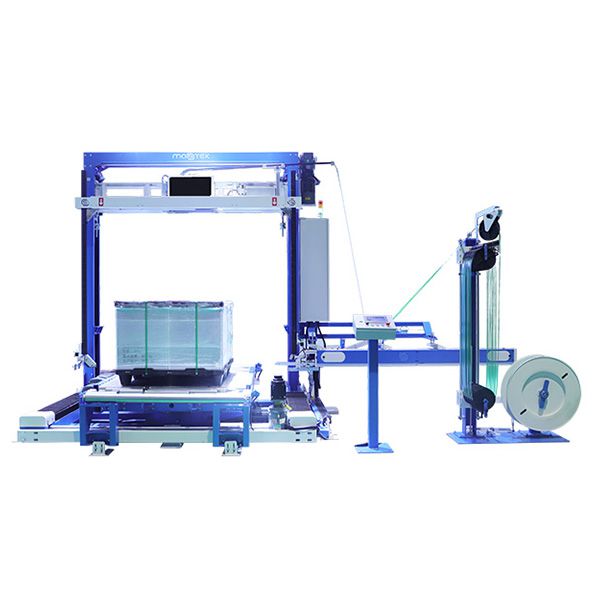

Carton Erector MO-01L

Length: 250-600mm Width150-500mm

Height:150-500mm

6 pcs sucker, and two folding bottom devices

Speed: 6-8ctn/min

SUS304 Stainless Steel

Carton Erector MO-01(stainless steel)

MO-01 with stainless steel 304 standard frame, and it's suitable for humid environments, widely used in the food industry.

Remark: Width on left Size(front view), output side on right

| TECHNICAL DATA | STANDARD FEATURES | ||

| Performance: | Cylinder | AIRTAC | |

| Throughput Speed | 10-12 Cases/Minute | Motor | GPG |

| Sensor | OMRON | ||

| Case (Outside Dimensions) | 250-500 mm L 250-400 mm W 120-400mm H | PLC | SIEMENS |

| Touch Screen | SIEMENS | ||

| Pre-caution for empty carton box | |||

| Case Types | Pre-caution for Tape used up | ||

| Wall Types | Single & Double Wall (test for multiple walls) | Safety door system | |

| Vertical forming box output | |||

| Bottom Seal | |||

| Tape | 48-72mm | ||

| Service Requirements | Certification | CE | |

| Air Supply | 6 Bar (80 Psi) | Machine Warranty | 1 year |

| Dedicated Electric | 220V, 1ph, 50/60Hz | ||

| Machine Data | Optional | ||

| Magazine infeed Capacity | 100 cases (approximate) | Bottom seal | Hot glue |

| Weight | 350 kg | For Small size box (48mm tape 15-20 ctn/min) | Length: 180-250mm Width: 80-200mm Height: 100-200mm |

| Dimensions | 2000mm L*2150mm W*1740 mm H | ||

| Outfeed Pass Height | 550 mm +/- 10 mm | ||

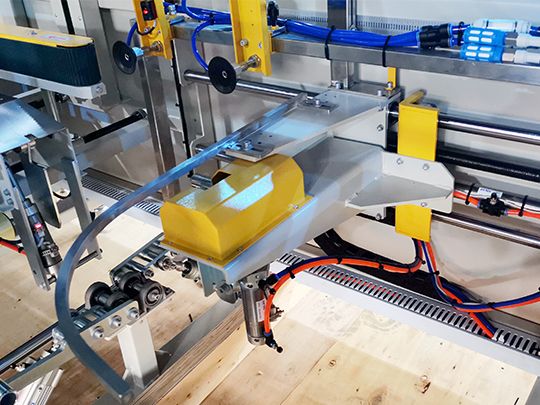

Automatic Carton Erector Machine Engineer Drawings

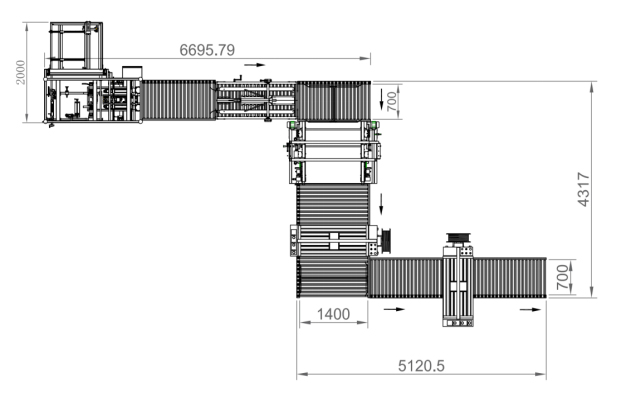

Automatic Carton Erector Packaging Line

Carton Erectors + flaps fold carton sealing machine + Carton edge Sealing machine | Carton Erector + flaps fold carton sealing machine + Carton edge Sealing machine + |

|  |

Application: A large-scale beverage company needs to package bottled drinks in cartons quickly to meet high demand.

Solution: An automatic carton erector machine is integrated into the packaging line, forming and sealing cartons rapidly. The machine ensures each carton is perfectly formed and sealed, reducing downtime and increasing throughput.

Benefits:

● Increased packaging speed to keep up with production.

● Consistent carton quality, preventing product damage.

● Reduced labor costs.

Application: A pharmaceutical manufacturer needs to package bottles of medicine securely and in a sterile environment.

Solution: Using an automatic carton erector with glue sealing ensures that each carton is securely sealed, maintaining product integrity and safety.

Benefits:

● Secure and tamper-proof packaging.

● Compliance with industry standards and regulations.

● Efficient handling of different carton sizes for various product lines.

Application: An e-commerce fulfillment center requires a fast and reliable way to form cartons for packing a wide range of products.

Solution: Automatic carton erectors are used to form cartons of various sizes on-demand, directly integrating with the order processing system.

Benefits:

● Flexibility in handling different carton sizes.

● Increased packaging speed to meet order volumes.

● Improved accuracy and reduced packing errors.

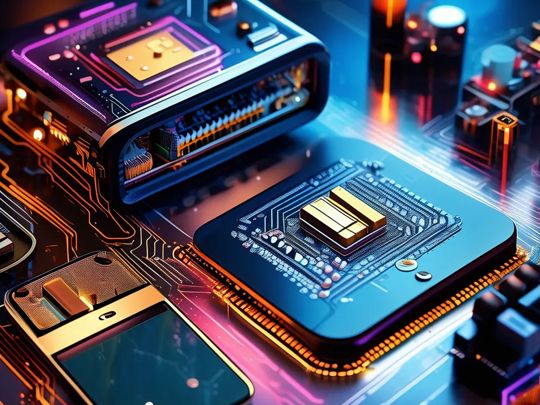

Application: An electronics manufacturer needs to package delicate components and devices securely for shipment.

Solution: A heavy-duty automatic carton erector with precision folding and sealing capabilities is used to create sturdy cartons that protect sensitive electronics during transit.

Benefits:

● Enhanced protection for fragile products.

● Reduced packaging material waste.

● Streamlined packaging process to meet high production rates.

Application: A cosmetics company needs to efficiently package a variety of products, from small bottles to larger boxed sets.

Solution: Implementing an automatic carton erector that can quickly switch between different carton sizes and sealing methods (tape or glue).

Benefits:

● Versatility in packaging different product types.

● High-quality, aesthetically pleasing packaging.

● Improved operational efficiency and reduced manual labor.

Application: A logistics company needs to form cartons rapidly for various clients, each requiring different packaging specifications.

Solution: Deploying a fleet of automatic carton erectors that can be programmed for different carton sizes and specifications.

Benefits:

● Customizable packaging solutions for diverse clients.

● Automatic Case Erecting Machines with rapid response to changing packaging needs.

● Increased throughput and reduced handling time.