MC-05

Length:150-unlimited Width:150-500mm Height:150-500mm

Side Drive with E-stop on machine

maximum load weight:25KG

2 or 3 inches tape head

Economical Model

Carton Sealing Machine MC-05Pro ( stainless)

MC-05Pro with stainless steel 304 standard frame, and it's suitable for humid environment, widely used in food industry.

All frame stainless steel

Side+Top drive

independent control box

high security system

Length: 250-600mm Width: 150-500mm Height: 150-500mm

Automatic Adjust Width and height

Speed: 10-12ctn/min

Side+Top drive

independent control box

high security system

| TECHNICAL DATA | STANDARD FEATURES | ||||||||||

| Performance: | Cylinder | AIRTAC /(MC-06FA Model) | |||||||||

| Throughput Speed | 20M/Minute | Electromagnetic Valve | AIRTAC /(MC-06FA Model) | ||||||||

| Case Size (Outside Dimensions) | L:150-unlimited W:150-500mm H:150-500mm | Motor | CPG | ||||||||

| Sensor | OMRON/(MC-06FA Model) | ||||||||||

| Operation | Air Flitter Valve | AIRTAC/(MC-06FA Model) | |||||||||

| fold flaps | Manual | Tape Cutter | SKD11(Japan) | ||||||||

| adjust size | Manual (MC-05FA model “AUTO”) | Motor Protector | Schneider | ||||||||

| Top & Bottom Seal | Electric Switch | Schneider | |||||||||

| Tape | 48-72mm | ||||||||||

| Machine Head | 3inch (2inch optional) | ||||||||||

| Service Requirements | Certification | CE | |||||||||

| Air Supply | NON (MC-06FA Model 6Bar ) | Machine Warranty | 1 year | ||||||||

| Power | 400W | ||||||||||

| Voltage | 110/220V, 1ph, 50/60Hz | ||||||||||

| Machine Data | Optional | ||||||||||

| Weight | 120KG | Top & Bottom seal | Hot glue | ||||||||

| Dimensions | 1020*900*1350mm(L*W*H) | Safety door system | with safety sensor | ||||||||

| Outfeed Pass Height | 600 mm +/- 150 mm | Output conveyor | custom made conveyor | ||||||||

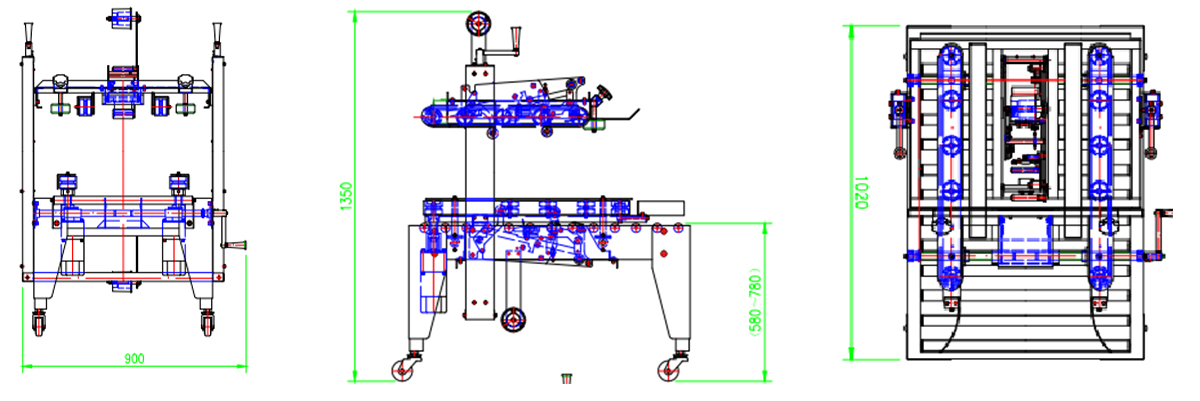

Engineer Drawing

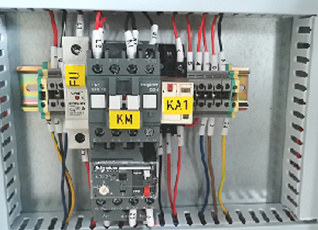

| Side drive + Top Drive system | Independent Electric Box | Safety system |

|  |  |

1. Two drive systems make the machine more durable 2. Both are suitable for heavy and high boxes | with main power switch, pause, power indicator button, let machine work more visible | 1. Two E-Stop buttons on machine 2. Schneider relays protect the motor from burning |

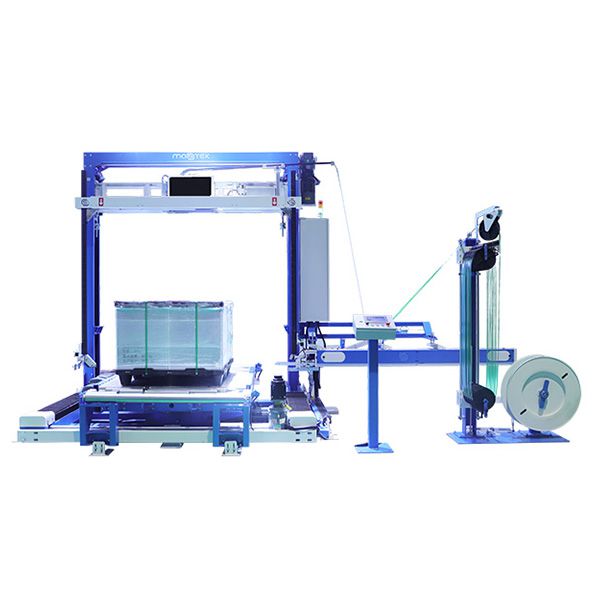

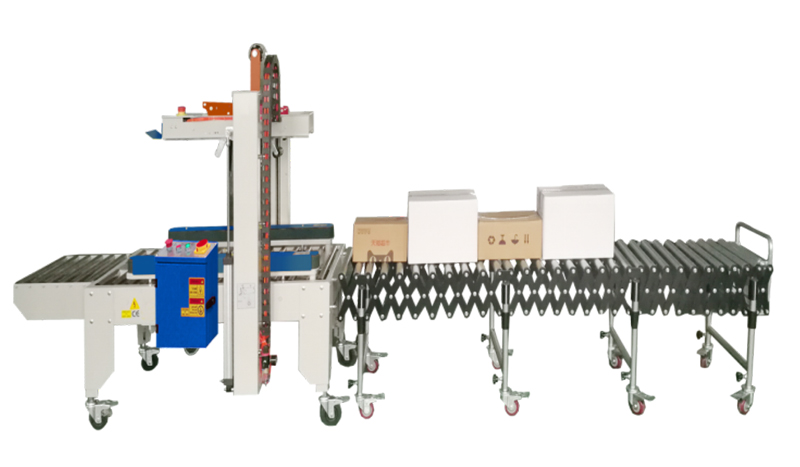

| Packaing Line: 1. Carton sealing machine + flexible Conveyor | 2.Carton sealing & strapping All in one machine |

|  |

| Roller /plastic colorful flexible conveyor 3-5m | PP strapping machine (maximum 500x500mm ) 2 straps |

A semi-automatic carton sealing machine is a piece of equipment used in packaging processes to seal cartons or boxes after they have been filled with products. Unlike fully automatic machines, semi-automatic carton sealers typically require some degree of manual intervention, but they still offer significant improvements over completely manual sealing methods. Here’s how they are applied in various settings:

● Small to Medium-Sized Businesses: Semi-automatic carton sealing machines are ideal for businesses that do not yet have the volume or budget for fully automated systems. They provide a balance between automation and manual labor, offering higher productivity than manual sealing while being more cost-effective than fully automated systems.

● Custom Packaging Operations: When the packaging requirements vary frequently or in small batches, a semi-automatic machine can be more flexible and adaptable than a fully automatic system, which might require more time to change setups.

● Supplementing Automated Lines: In larger facilities, semi-automatic carton sealers can be used to supplement fully automated packaging lines during peak seasons or for special orders that don’t justify reprogramming the entire line.

● Temporary or Seasonal Increases in Demand: During times of increased demand, such as holiday seasons, semi-automatic machines can be brought in to handle the surge in packaging needs without requiring a long-term investment in additional fully automated machinery.

● Quality Control: In some cases, having a human operator involved in the sealing process allows for immediate quality checks and adjustments that might be harder to implement in a fully automated environment.

● Training and Development: Semi-automatic machines can serve as a stepping stone for operators who are transitioning from manual to fully automated systems, providing a middle ground where they can learn about mechanized packaging processes.