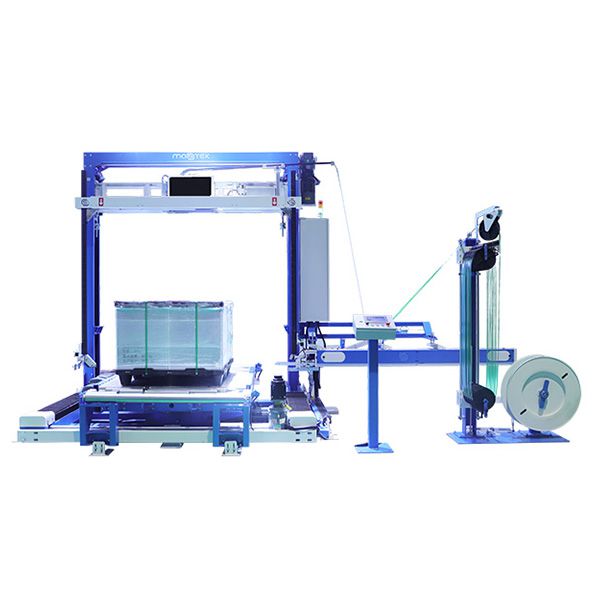

1. NON STOP Loading Magazine design: Replenish blanks while machine operates. No need to stop machine to load magazine, making it more convenient for the operator and improving work efficiency.

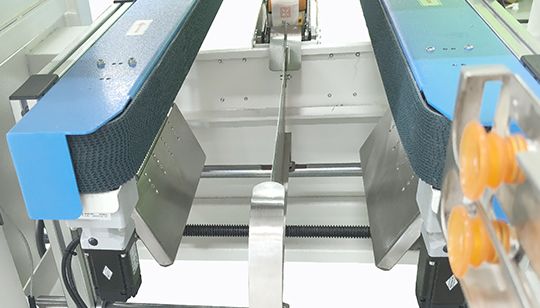

2. The chain drives the empty box forward so that the box is always in the correct position.

3. Simple and fast magazine adjustments

1. Reliable Servo motor drives a robot arm with 8pcs powered Sucker to keep the blank in the correct position after it leaves the magazine.

2. The robot arm form the box by length and width on both side. Both leading panels were firmly held in place. Automatic 90 degree forming design keeps the box 100% square at all times.

1. MO-02 output belt is driven by a servo motor system, making the box move more smoothly before folding the bottom.

2. MO-02 use a large folding plate, fold the bottom folding plate to align before sealing.

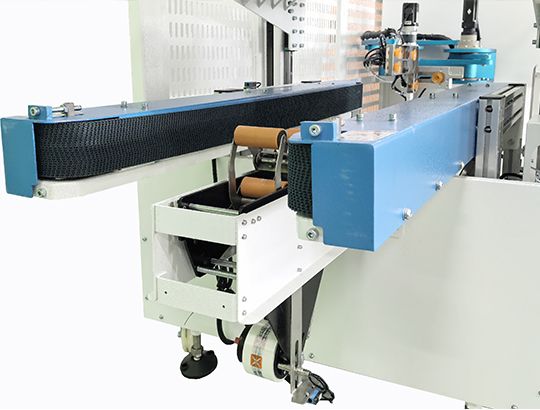

1.MO-02 tape head dispenser outside design to make changing paper tape easier and safer.

2.MO-02 Pre-caution for Tape used up, which can monitor the status of the tape in time.

| TECHNICAL DATA | STANDARD FEATURES | ||||||||||

| Performance: | Cylinder | AIRTAC | |||||||||

| Throughput Speed | 20-25 Cases/Minute | Motor | ALL SERVO Motor control | ||||||||

| Sensor | SICK | ||||||||||

| Case (Outside Dimensions) | 200-450 mm L 150-350 mm W 150-350mm H | PLC | INOVANCE | ||||||||

| Touch Screen | IoT Screen | ||||||||||

| Pre-caution for empty carton box | |||||||||||

| Case Types | Pre-caution for Tape used up | ||||||||||

| Wall Types | Single & Double Wall (test for multiple wall) | NON -STOP load magazine design | |||||||||

| Safety door system | |||||||||||

| Bottom Seal | Vertical forming box output | ||||||||||

| Tape | 48mm/60mm/72mm | ||||||||||

| Service Requirements | Certification | CE | |||||||||

| Air Supply | 6 Bar (80 Psi) | Machine Warranty | 3 years | ||||||||

| Dedicated Electric | 220V, 1ph, 50/60Hz | ||||||||||

| Machine Data | Optional | ||||||||||

| Magazine infeed Capacity | 100 cases (approximate) | Bottom seal | Hot glue | ||||||||

| Weight | 600 kg | Output conveyor height | if over 600mm | ||||||||

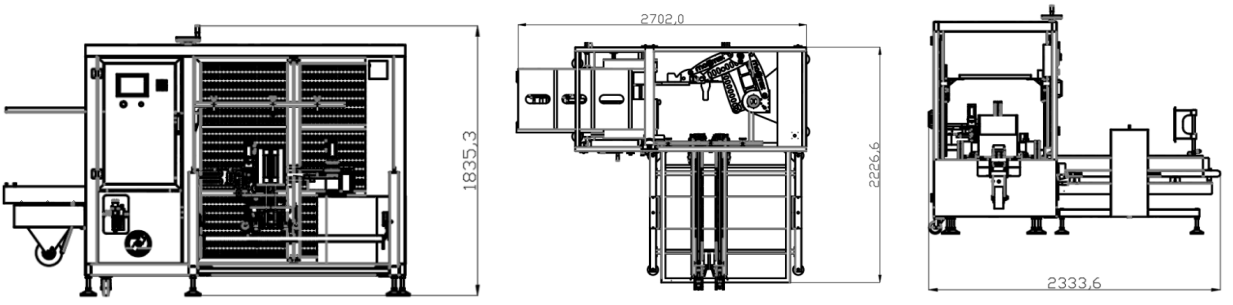

| Dimensions | 2702*2226*1835mm L*W*H | ||||||||||

| Outfeed Pass Height | 500 mm +/- 30 mm | ||||||||||

Engineer Drawing

Food Packaging: Carton erector machines are frequently used to package food items like cereal boxes, milk cartons, pizza boxes, and other types of food packaging. The machines can handle different sizes and shapes to accommodate various products.

Pharmaceuticals: In the pharmaceutical industry, these machines are used to form cartons for packaging medicines, ensuring that they meet strict hygiene standards and comply with regulatory requirements.

Cosmetics: Cosmetics companies use carton erectors to create packaging for products such as lipstick, perfume bottles, and skincare products. The machines can be adjusted to produce small, precise cartons that are often required in this industry.

Electronics: For electronics manufacturers, carton erectors help in creating protective packaging for devices like smartphones, laptops, and other gadgets. These machines can form sturdy boxes that ensure the safe transport of delicate electronic equipment.

Logistics and Shipping: In logistics and shipping, carton erector machines are used to create shipping boxes that can be customized to fit specific items or product dimensions. This helps reduce the space needed for storage and transportation.

Retail Packaging: Retailers often require attractive and functional packaging for their products, which can be achieved using carton erector machines. They can produce retail-ready packaging that is designed to stand out on store shelves.

Customized Packaging Solutions: Businesses that require unique packaging solutions can benefit from carton erectors, as they can be programmed to form custom shapes and sizes according to specific needs.

Environmental Packaging: With an increasing focus on sustainability, carton erectors can also be used to create eco-friendly packaging solutions made from recycled materials or designed to be recyclable after use.